Design a Car- Not only are automobiles significant transportation technology, but they are also beautiful works of design. Automotive design might be something you’d be interested in pursuing if you love how cars look and work! However, if you don’t know a single thing about cars or design, it might seem impossible. Fortunately, almost anyone can easily learn how to design a car, whether they draw by hand or on a computer.

How to Design a Car

A few of the most important “rules” of How to Design a Car design are attempted to be explained on this page. You might be thinking that there are no guidelines; surely each designer is free to do as they please? That is evidently correct, but cars must adhere to regulations and laws regarding type approval, which imposes constraints. That still leaves a lot of room for creative expression. I’m primarily referring to common aesthetic practices and traditions, which are intricate enough to perhaps be discussed multiple times here.

How to Design a Car Details

| Article for | How to Design a Car 2024 in Details Full Guide |

| How to Design a Car 2024 in Details | Click Here |

| Category | How to guide |

| Official website | Click Here |

click here:-How to Make an Electric Race Car 2024?

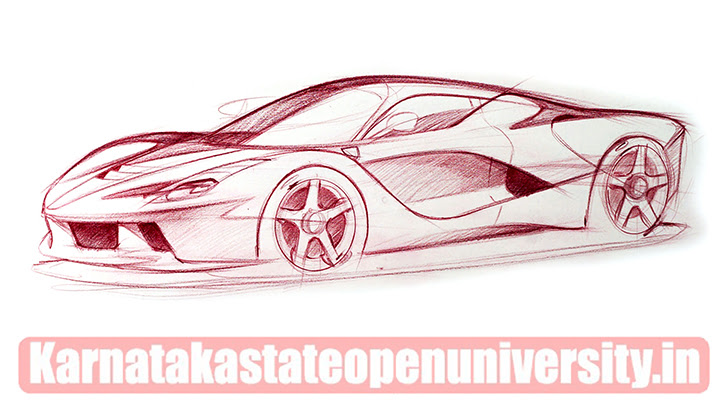

Drawing and Sketching

The designers of each concept car project consider the fundamental beliefs and principles they wish to convey at the outset. We must determine the fundamental characteristics we want to imprint on the new vehicle, such as dynamic, sporty, how much emphasis we will place on its roominess, functionality, and so forth. When describing the initial stage of defining the showcar’s future face, designer Peter Olah says, “The main tools we use in these early stages are pencils and paper, as well as markers to highlight some of the contours.” The very first design sketches are just rough drafts. Emotions take center stage during this phase, which focuses on achieving clarity and organization.

After rough drafts on paper, more detailed sketches are made on digital tablets, which are the first drawings to show the car’s surfaces and overall dimensions. The Chief Designer and the Board receive these. Detail views, cross-sections, and the final drawings that will be used as input data by 3D modellers follow this stage.

Digital Design Model

The Digital Design Model is made up of the visions and design data of the designers. According to digital modeling specialist Petr Havlek, “our ambition is to harmonize all expectations around aesthetics, ergonomics, and functionality with what is technically producible.” After that, a 3D model is made on a PC, details are added gradually, and a group of designers and engineers talk about everything. The next step is to create a model out of clay while testing each component’s functionality and making additional adjustments. The final Digital Design Model’s components are all designed to the finest detail; if necessary, each part is further modified on a PC. The final data generated in this manner are then put to use in the actual car’s production.

Also Check- How to Remove Tree Sap From Your Car

Clay Model

After the initial computer models and sketches, a 1:1 clay model follows. Clay modeling is one of the traditional methods for designing things. It gives designers a very good idea of how the future car will look. To soften the clay, a furnace is heated to 55-60 °C. The heated, soft clay is then applied to a metal chassis with struts and a skeleton in a layer about 6 cm thick. The required shape is created by designers and modelers; the clay begins to harden after approximately 15 minutes on small surfaces.

After that, special tools are used to work on the clay layer. The interior modeling approach is comparable, with the exception of a slightly thinner clay layer. Moreover, the modeling clay is extremely heavy—the “clay VISION E” weighs approximately 2.5 tonnes. Special foils are then applied to the surface of the clay model to give the car a glossy appearance and make each shape stand out. The final clay model is then painted like a car.

Interior

The interior model is a one-to-one sit-in box. To make sure that everything works in terms of both aesthetics and ergonomics, the designers must test everything in the interior. The method of making the model is the same as the one used to make the exterior model. The only difference is that the interior modeling process uses more prototype parts and 3D printing.

The goal is to make the impression as close to the future as possible. The team further modifies the key concept data and tests other options in parallel with the clay model. Special foils are used to cover the clay interior model so that the different surfaces look like they do in the real car.

Lights

The VISION E’s designers collaborated with Lasvit, a Czech crystal glass specialist, because the lighting and glass components are the car’s “jewels.” The company provided numerous glass details, including those for the lighting system, for the exterior as well as the interior.

the lights all over the front mask, including an element that is backlit under the edge of the bonnet. The showcar’s personality is brought to life by the lighting design, which also shows our plans for future models. New technologies are referred to in the luminous signature. Petr Nevela explains the rationale behind the lighting design, “The impressive combination of art and technology is highlighted by glass and light,”

Check Also- How to Buff a Car 2024 in Details

Colour and Materials

Each member of Color & Trim, the group in that charge of interior details, seat materials, and body colors, among other things. is in charge of a particular area, such as leather, textiles, interior colors, exterior paints, decorative strips, etc. Computer visualizations are used to bring materials and colors together. In small boxes (vehicle sections), where the various parts can be changed, hands-on demonstrations take place.

Project Coordination

The showcar development process is always quicker than that of series production vehicles. The VISION E is a revolutionary product because it is solely an electric vehicle, and we were unable to use any of the existing platforms for it. We started from scratch in every way, including the body, the door-opening system, and the electrically controlled strut-operated tailgate-opening system, says Project Coordinator Daniel Edr, describing some of the specifics of the concept car project. The spaciousness of the interior, the floor made of smooth veneer, and the frameless side doors—the rear doors opening in the opposite direction of the vehicle’s movement—are also distinctive features. When climbed into, the vehicle appears to be extremely comfortable due to the absence of a conventional B-pillar.

Throughout the showcar development process, materials and documents for key expert meetings and Board meetings are continuously produced. According to Daniel Edr, “My responsibility is to prepare the concept and then harmonize all of the inputs contributed by the respective Design teams.” At this point, the work of tens of people who have put in a lot of effort has been completed.

Related Post:-

How to make phone calls using your Windows or laptop 2024?

Get a Car Dealer License to Sell Cars 2024